Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Model No.: QZDMTX-440

Brand: Helper

Applicable Industry: Hotels, Food &Amp; Beverage Factory

Out-of-warranty Service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Status: New

Application: Food

Type Of Packaging: Cartons

Packaging Materials: Wood

Degree Of Automation: Automatic

Power Type: Mechanical

Place Of Origin: China

Warranty Period: 1 Year

Core Selling Point: Competitive Price, Automatic, High Productivity, Multifunctional

Mechanical Test Report: Provided

Video Factory Inspection: Provided

Core Component Warranty Period: 1 Year

Automaticity: High Automation

Material: Stanless Steel

Type: Pastry Processing Machines

Packaging: Seaworthy wooden case

Productivity: 300-1600kg per hour

Transportation: Ocean,Land

Place of Origin: China

Supply Ability: 20 sets per month

Certificate: ISO9001-2008, CE

Port: tianjin

Payment Type: L/C,T/T

Incoterm: FOB,CFR,CIF,FCA,CPT,CIP

Introduction of Automatic Noodle Production Line

This production line can produce instant wet noodles, quick-frozen cooked noodles, semi-dry noodles, fresh noodles, etc.

The production line is mainly composed of vacuum dough mixer, dough maturing conveyor, composite tablet press, dough belt elevator, dough belt maturing machine, continuous calender, quantitative cutting system, multi-function noodle cooker, noodle washing machine, PH adjustment equipment, packaging It is composed of machine, confluence detection equipment, sterilization equipment, cooling equipment, etc.

Features of Noodle Production System

1. Processing under the vacuum negative pressure, makes the protein fully absorbing moisture in shortest time, forms the best gluten network and right status tenderness of dough.

2. Wave rollers, and continuous dough sheet aging system.

3. To produce cooked noodle products with different tastes (such as Udon Noodle)by various techniques such as boiled type and steamed type.

4. By adjusting the process of cooking, cooling and acid soaking, drying, sterilization, etc., it can meet the specific processing requirements of customers.

Major Performance Data of Noodle lines

Model Width of Roller(mm)

Power(kw) Capacity(kg/h) Component Parts Dimension (mm) QZDMTX-230

230mm 30.2 300 15 128000*1000*2500 QZDMTX-440

440mm 36 700 15 156000*1200*2900 QZDMTX-800

800mm 70 1600 15 360000*1200*2900

Noodle production line films

| Large Scale Noodle Line, roller width 440,800mm | Small Type Noodle line, roller width 270mm |

| | |

Details and Photos of Noodle production line

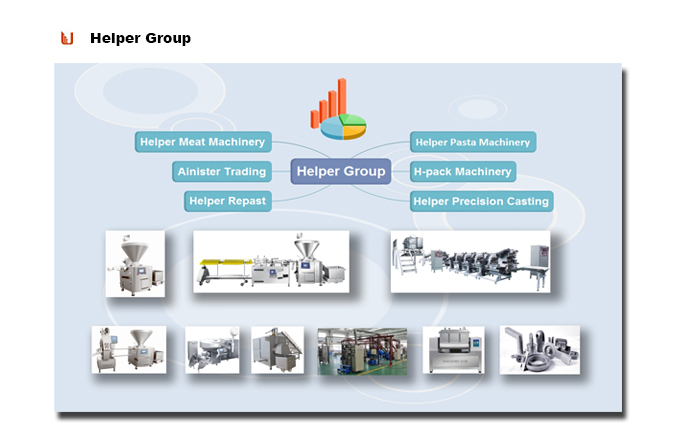

About Helper Machinery Group

Factory Overview---To understand our production capacity and company strength

|  |

|  |

Product Categories : Bakery And Pastry Machines > Noodle Production Lines

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.